This article was written by someone who only knows buzz words. They said it’s “not just the silicon(edited from silicone), but the entire microcontroller” what do they think processors have other than silicone?

Edit: silicone->silicon

They’re referencing the package as a whole, plastic casing, gold internal wiring, etc. and the silicon die in the center of it all.

This still makes no sense, because the gold wiring is a huge cost. Why dafuq wouldn’t current manufacturing encourage smaller packages? And there has been a push to make things thinner since ad memorium, so why wouldn’t they have made the die slimmer?

Edit: good to know the hive mind still exists.

You’re asking why they didn’t make the package thinner than like .1mm thick…?

Or are you commenting on some sense of surprise that someone would want to make small things, or something? If so, not sure what you’re referring to.

I’m saying there is no reason to say this microcontroller is vastly different from current products on the market.

Sure there is.

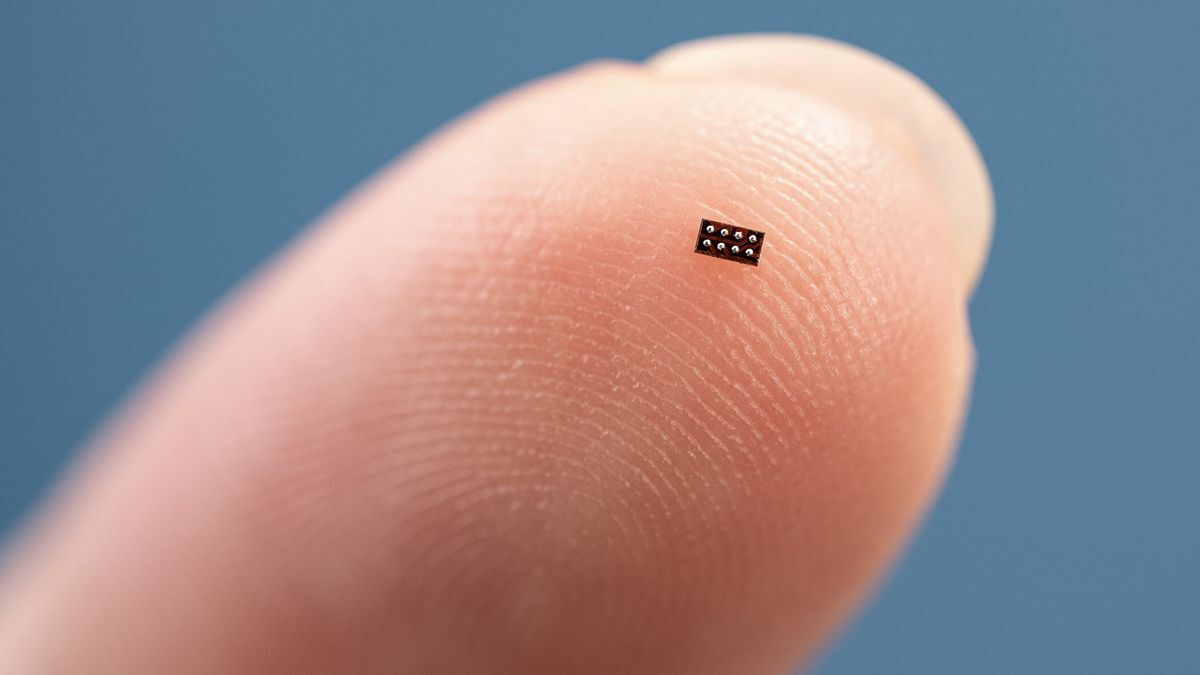

As far as I know this is the smallest full microcontroller package on the market. Which is what makes it interesting and why we are here talking about it.

Are there others?

Work on this stuff:

Thermal reasons, having enough pins and routabke pads on the board so you can land them from the package, mechanical properties (strong enough not to get squished).

We do what we do because it’s the cheapest way that covers the requirements and is still easy to assemble.

We slowly move to smaller pitches, but they’re more expensive to deal with, you need more accuracy on your pick and place and the tolerances on your pads and soldermask are smaller.

Correct me if I’m wrong, but there is no silicone at all in microprocessors but silicon.

You’re right, I don’t type that word into my phone much so the autocorrect effed me. I’ll edit for clarity.

You forgot to edit the second silicone at the end of your sentence.